Flexible insulated copper busbars

Unbelievable, Zhao Liying and Feng Shaofeng suddenly announced their marriage on Oct 16, 2018, 10:07. The time and date precisely are the two date of birth. I am trying to click on Sina Weibo to see what happened, but it suddenly exploded. Not publishing the love affair, rather than who directly show marriage certificate.

Back at the farm, Bridgold also has extraordinary news. Flexible insulated copper busbars occupy almost half of the braided copper connectors workshop.

Introduction

Flexible insulated copper busbars, also known as laminated insulated shunt, flexible busbar, is made up of layers of highly flexible flat thin copper conductors, and the outer layer is made by extrusion coating the insulating layer.

Structure and composition

- conductor

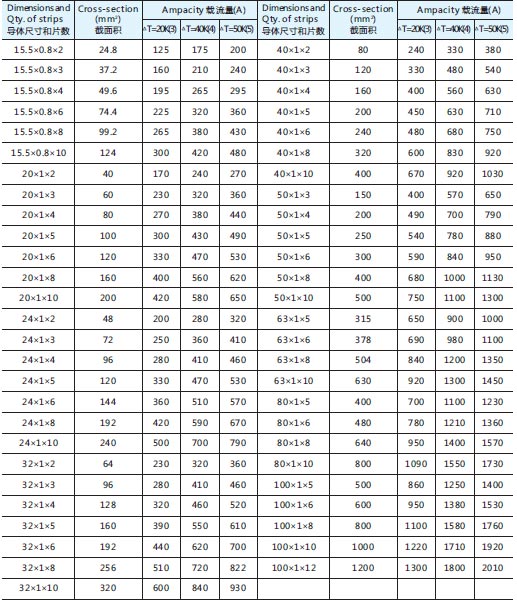

The conductor of flexible insulated copper busbars adopts T2 flexible copper strip, which can be divided into bare copper and tinned copper. The copper strip has a specification of 15.5 x 0.8, 20 x 1, 24 x 1, 32 x 1, 40 x 1, 50 x 1, 63 x 1, 80 x 1, 100 x 1, and the number of lamination layers is from 2 to 12.

- Insulation

The insulating layer of flexible insulated copper busbars are currently available in two special materials: PVC and TPE. TPE has the features of LSOH (Low Smoke Zero Halogen). Insulation is black.

- Standard

There is no special standard for flexibel insulated copper busbars worldwide. U.S. borrows UL758.The sub-line standard is used for production certification. BRIDGOLD started production with reference to GB/T5023 insulated cable standard and UL758 electronic line standard.

Main Features

- Easy processing

Since the copper conductor can slide freely within the insulating layer, the flexible insulated copper busbars have an infinite bending torsion characteristic. The thickness ratio of the copper bandwidth is large, so that it can be easily bent in the thickness direction and has high rigidity in the width direction, which theflexible insulated copper busbars can bend any space configuration by hand or with a simple tool, which is convenient and Install wiring.

- High current carrying capacity

Due to the skin effect, when passing through the alternating current, the actual current inside the conductor is small, the current is concentrated on a thin layer adjacent to the outer surface of the conductor, and the multilayered flat conductor structure of the insulated soft busbar allows the same conductor cross-sectional area to carry a larger Pass current. The following is a comparison of the required cross sections for insulated soft busbars and ordinary round cables under three current carrying capacities:

- Easy to install

After the insulated flexible copper busbar is bent and punched, the spatial shape of the structure can avoid the interference area, and the original shape can be easily restored after bending, and the contact surface and the terminal can be directly fixed.

Application

Due to the excellent characteristics of the flexible insulated copper busbars, it has become the first choice for electrical wiring, and will gradually replace the application of the cable in the electrical wiring. The hard busbar of the non-main structure will be gradually replaced by the soft busbar.

Specification